1988 MARK ZEH

"J. Zeh"

Story of the bike

This bike was part of an auction from a church or so, although it popped up for sale on eBay. It looked like a very interesting bike with many small unique details.

When it arrived, I discovered that instead of a serial number, there is the name "J.Zeh" stamped into the frame under the bottom bracket.

I contacted Mark Zeh to get more info about this bike, in order to restore it sometime soon:

General:

Something about this era is how quickly everything was changing. Mountain bike technology was really rapidly transitioning from being adapted from traditional high-end road bike building methods toward motorcycle building methods. This bike really marks a kind of turning point.

I built that bike for my ex-wife, who is a really great cyclist.

Racing History:

To the best of my memory, we got the original painted frameset back late in the same afternoon that we headed off to the Chequamegon Fat Tire Festival in Hayward, Wisconsin the Fall of 1988. I built the bike up in our shop, while J packed up for the race weekend, then we loaded up and drove there in the dark. I don't think the bike has any distinguished palmarés, since I recall some disappointing stories about wrong turns and many extra miles ridden during that particular racing foray.

We had this bike around us for a long time, so I may have some fotos of it at events.

We weren't pro-level racers, so no World's or big-money events. This was pre-internet, so the MTB racing scene was very local and still pretty disorganized at this time. Unfortunately I no longer have my magazine archive from that era, so I can't tell you how many NORBA events there even were. I am sure that this bike appeared in several Chequamegon 40 races, a 24 hours of Moab, events at the Crested Butte Fat Tire week and maybe some Laguna Seca events near Monterey.

We raced pretty much everywhere we could, so for us, most weekends of the 80s and 90s were a race somewhere: road, offroad, velodrome, duathlon, cyclecross, x-c ski events, you name it.

Frame:

I believe that the bike was originally a darker violet metallic, with white stickers. I believe that it was resprayed Lemon Ice by Mark Leonardson during my sponsorship of the Cycle Goods women's team in the mid 1990s.

The frameset is built from the lightest set of Tange Prestige Mountain tubing that I could compose-- it has some road tubes in it. I believe the top tube is butted 0.7mm-0.4mm-0.7mm and seat stays are the thinwall road version (these were probably 0.6 mm). I probably bought put this set of tubing together out of parts and pieces that I bought from Terry Osell, a custom framebuilder in Minneapolis/St. Paul. He and his wife Joan, were amazing supporters of the US Midwest handbuilt bike scene when I was active there.

In the 1980s, "common knowledge"; the word of all of the experienced builders around me (I still remember being lectured by Cecil Behringer about this); and tradition still had it that low temperature silver brazing was the best joining process to create the highest quality framesets. I was doing a lot of fillet brazing at the time (especially for the new Mountain Tandems and other non-conventional stuff I was building), but likely silver-brazed this since I wanted to try out some of the investment cast parts you see on the frameset (the lugs, dropouts, and BB shell). The Long Shen lugset (they were a new-ish company at that time) has been worked over, to make the curves and points more-defined. As evidenced by the fillet-brazed fork and Tange Prestige uni-bar, this bike was made right at the point where I was developing good fillet brazing skills. Five years later, I would commonly be assembling framesets like this with TIG welding, which yields a much lighter frameset (no lugs or heavy brazing materials).

Tange Prestige is a heat-treated super steel from Tange in Japan. It was the first ultra-strong heat-treated steel that was also ductile and workable with ordinary tubing cutters, saws, and files. Previously, the only ultra-high strength steel that I could get hold of had been Reynolds 753 (I am a 753 certified master framebuilder), which was very brittle and also very difficult to work. The high strength of 753 was accompanied by glass-like hardness and very low ductility, so it was very difficult to cut and file. It was also expensive, of variable quality (measured dimensions could vary quite a lot from what was in the catalog), and often hard to get. In summary, nothing for a shop that was going to produce a lot of bikes, or switched materials often. Prestige changed all of that. This bike is probably built from one of the first Prestige MTB tubesets available in the US.

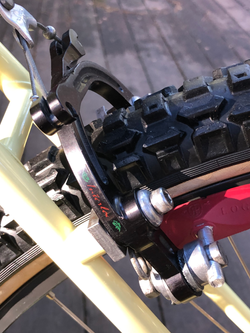

Note that the bike has a delrin cable guide under the BB. At this time, everyone was still experimenting with cable routing, to try to figure out what to do with shifting function reduction/blockage from mud/grass/water. The concept of the mountain bike emerged from the california coast, where this was a minor issue. We were in the Midwest, so mud, leaves, water, etc were daily issue and fun-killer. I spent years trying different types of cable routing, in a one-frameset-at-a-time way. Delrin has the promise of low-friction and low surface energy, so nothing is supposed to stick to it. In reality, under BB cable routing proved not to work. This may be the last MTB that I built with this cable routing configuration.

The through top-tube brake cable routing method I used is borrowed from the road bikes I had been building since the early '80s. I wanted to increase the stiffness of the rear brake feel by limiting the amount of cable housing, but also find an aesthetically nice solution. The rear brake cable is guided through an internal tube, with cable stops on each end. The internal tube is non-ferrous, so that water and guck don't cause the cable to rust into the internal housing. I also sized the internal tube to allow for a delrin cable liner.

A word on the handlebar/stem: At this point in time, we were first able to get unpainted Tange Prestige mountain bars-- I believe from QBP in Bloomington, Minnesota. The butted section in the center was heavy enough to allow for fillet-brazed, or welded construction. From the top cap, it looks like I sourced the quill assembly from QBP, who used to sell a good selection of framebuilding parts. The extension tube is some 0.9mm 4130 oval stock that I used to get from Nova Cycles Supply, for use as tandem top tubes. The Prestige sticker if a fork sticker from a respray sticker set. The Prestige bars did come with their own sticker, which had raised gold lettering on a textured gold background, but, for some reason, the sticker was a bit wider than the straight section of the bars, so you couldn't actually place it on the bar without it wrinkling. I still love the feel of an integrated bar/stem-- and it also looks really great-- glad that so many modern companies are producing these now.

Components:

The component build on J's bike looks like it's nearly all-original, with the IRD rear brake (interloc racing design, located in Selma Oregon-- Rod and Ray...), American Classic seatpost and Seatpost QR, Bullseye crankset (I used to order a lot of stuff from Roger Durham, who was in Burbank, CA at the time), Suntour XC brake levers, etc. This was a high-end build at the time, that didn't use Shimano's system stuff.

J used to use an Avocet Women's saddle, which is still on this bike and was the first decent-ish modern saddle for women. I used to have a big box of saddles in my shop for people to try-- I think that this was the best of the bunch for women at the time.

This bike had black mushroom grips as its original equipment (like "as arrived"). The Onza bar ends are also original.

The bike looks like it still has the original bottle cage, clip for the mini pump, and clamp-on finger to try to prevent dropping the chain, when shifting to the little ring, it mostly worked pretty well.

It's cool that the big chainring seems to have been replaced! Respect for wearing out your big chainring!

This bike would have had Suntour XC Pro pedal (x-shaped body, with sealed bearings) and Specialized MTB toeclips. If it didn't have XC pro pedals as original equipment, it probably briefly had the original XC, or suntour superbe track pedals.

We would have had either the classic Specialized Ground Control or a Ritchey tyre on this for offroad racing. We changed a lot, since we had a lot of thing to try and traveled often. At the time, the hot spec (from BMX, I think) was a smaller tyre, like a 1.9, on the back and a 2.1 on the front. This bike was probably built before it became possible to really play around with this.

Shifting: The Deore shifters are original. At this time, the indexed shifting systems on the market still weren't reliable enough for midwest racing (grass/sticky mud/water mixture + the cable routing puzzle I wrote about)-- in a long race (like the chequamegon 40), it was common for the early indexed systems to just stop working in a position somewhere between gears about halfway into the race. Friction shifting gave you that analog find-a-gear thing that allows you to keep going (sometimes to a point about 2/3 into a race, but that's an advantage), when things start not working. I think I used the XCD because of its capacity, or maybe I had a sample lying around the shop (a lot of stuff on our personal bikes are samples or development parts). I also used to really like Suntour components and am still unhappy that they didn't keep developing. This may have been one of the lighter rear derailleurs, too.

Best Regards,

Mark Zeh

Photo Gallery

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

How the bike arrived

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |